Project Blog

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

Scarf joint and barn update

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

Scarf joint and barn update

Classic Architecture Meets Sustainable GreenTechnology

August 2010 Update and Knee Brace Primer

Welcome to the mostly hot and humid summer of 2010. I've been trying to maintain momentum on framing my own barn, while keeping a couple of other design-build jobs going. This has also been the season that I've resolved to get my own body working a bit better, leaner and more flexible. My wife and I have been working out almost every early morning, unless the heat and humidity are so bad that only deerflies can thrive. We alternate running, mt. biking, and rock climbing, and add a bit of free weight work and yoga to the mix. These morning workouts have made the work days go especially well - though sometimes it's hard to roll out of bed and hit the trail, it sure feels good once we've done it!

This past week I finished up the top plates and installed them with the help of my brother and the barn is starting to look like an actual building..

Welcome to the mostly hot and humid summer of 2010. I've been trying to maintain momentum on framing my own barn, while keeping a couple of other design-build jobs going. This has also been the season that I've resolved to get my own body working a bit better, leaner and more flexible. My wife and I have been working out almost every early morning, unless the heat and humidity are so bad that only deerflies can thrive. We alternate running, mt. biking, and rock climbing, and add a bit of free weight work and yoga to the mix. These morning workouts have made the work days go especially well - though sometimes it's hard to roll out of bed and hit the trail, it sure feels good once we've done it!

This past week I finished up the top plates and installed them with the help of my brother and the barn is starting to look like an actual building..

Over the next couple of weeks I plan to cut and install the roof framing. It will look very similar to a

house frame that I cut last winter.

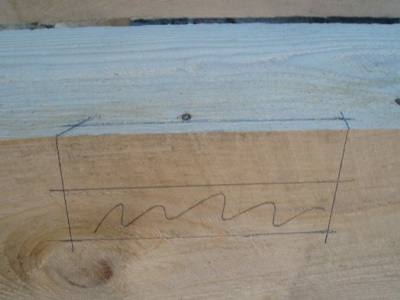

In keeping my promise to provide step by step instruction in joinery, I will lead you through cutting and

fitting a knee brace. Though it's a relatively simple task, knee braces are so ubiquitious that an efficient

process will really pay off in terms of time saved and crisp asthetics. The purpose of a pair of opposing

knee braces is to stabilize a system of posts and beams laterally. Though they provide some support in

tension, their real strength is in compression, and thus they need to be used in opposing pairs. Here are

pictures of a knee brace, and a template they I use to lay out both the knee brace and the mortices that

that house it. Notice the small ears on the template that allow setting the brace 1/2" into the timbers.

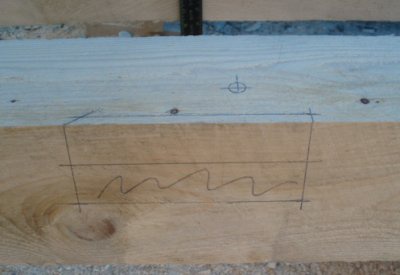

Now we'll hold the template against the timbers and layout the mortices.

After taking the marks from the template, we'll

give them depth, in this case 3", which is the

thickness of the braces.

Next we'll lay out the position of the hole for the peg. In this case it's 2" from the square side of the brace

and 1 -1/2" from the shoulder. The framing square has a 2" and a 1-1/2" leg. We will ultimately "draw bore"

the brace, meaning that we will stagger the holes on the mortice and the tenon so that driving the peg

forces the joint tight.

To bore the hole, I use a home made boring jig. It's basically a 6x6 that I've driven a hole in with a drill press.

You/we might notice that I alternate between first and second person narration. There are a few reasons for this:

1- to pretend that I have more help than I really do, 2- To lull you into thinking that we're working together, and

3- because I'm more qualified to design and build things that I am to describe the process in writing. .....To

remove wood to create a mortice, I use a chain morticer. Without this tool, you could use a drill and then

square the mortice with a chisel.

Next, I use a circular saw to cut the outline of the brace housing, and then clean it up with a sharp framing

chisel.

To finish up the mortice side of this process, I coat the joint with "anchor seal", which is a liquified parafin used

to slow the loss of moisture from the timber and minimize cracking, checking, and twisting.

Now we'll layout and cut the actual braces, using the same template, and layout the holes the same way as

we did on the mortice side.We'll offset the holes approx 1/8" to provide "draw".

We'll cut the decorative curve with a portable bandsaw, a very hand tool for timber framing.

Now we'll cut the tenon ends of the brace with a 10" circular saw.

If you look carefully into this hole, you can see the

"draw", the slightly offset holes that keep the joint

tight.

And the final assembly, including pegging the braces into place. Enjoy the rest of summer and by all means

stop by my place in Monterey to check out the barn and other projects in person. Please also notice the list of

blogs at the bottom of this page and feel free to browse them. The geometric design blogs seem to be

favorites of many people.