Basic Traditional Toolchest

approx. 26" long, by 17" deep, by 14" high

Following is a step by step pictoral outline of the toolchest that the Heartwood

class will build. It is traditionally proportioned to be a good size to carry to a

jobsite.

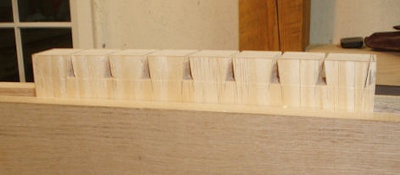

The main carcase pieces are cut to size and

dovetails are laid out. I lay out tails first

and pins second.

Tails are cut with a dovetail saw.

Tails are "wasted" with a turning saw.

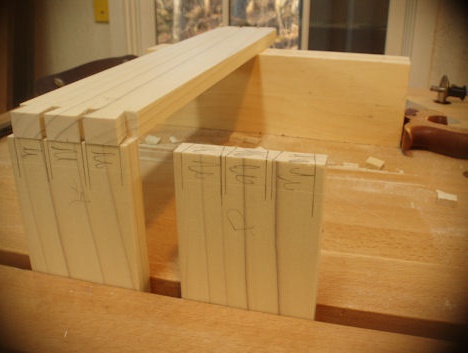

Pins layed out from tails.

Wasting pins with a turning saw.

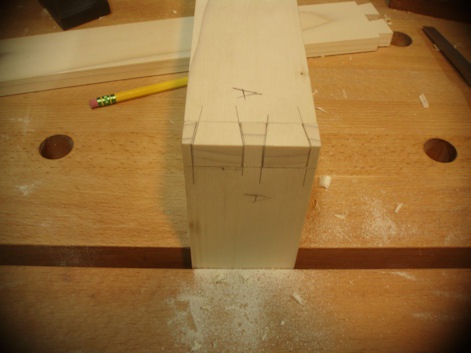

Pins cut out. I use a "Moxon" vise to cut

dovetails in. It brings the joints up to a

good height for layout and cutting and

holds boards securely for working on

their ends.

Dry fitting the carcase sides.

Planing the corners off after gluing. I use

"Krenov" style hand planes which I build.

Nailing bottom boards on.

Oak runners on underside of chest.

Cutting dovetails in the plinth.

Wasting pins with a turning saw.

Dry fitting plinth.

Glueing plinth together and to carcase.

Laying out boards for frame and panel lid.

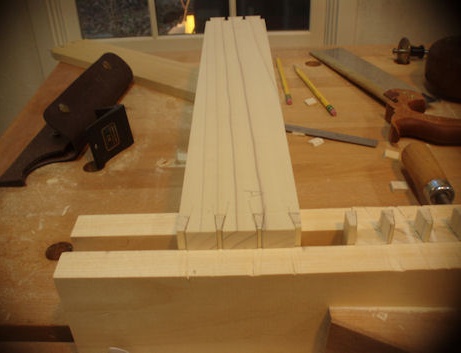

Cutting tenon shoulders.

Cutting tenon cheeks with a tenon saw.

Adjusting tenon thickness

with a rabbit plane.

Adjusting shoulder with

a shoulder plane.

Ploughing dadoe for panel

with a Stanley 45.

Laying out mortise.

Cutting mortises.

Dry fitting frame.

Frame and panel.

Carcase with plinth.

Constructing dust apron which

will be attached to frame and

panel lid.

Using butt mortise plane to make hinge mortises.

Cutting hinge mortises in carcase.

Using gimlet to drill screw holes.

Assembled chest and chest with sliding tray added.

Add a coat of mustard colored

stain to the exterior and this one

is complete. This is a very

pleasant project that took me

approximately 18 hours. The

carcase, bottom, and lid panel are

eastern white pine, and the

plinth, lid frame, and tray are

poplar. The material was

dimensioned with power tools

(band saw, jointer, planer, table

saw), which took about an hour.

All of the joinery, planing,

sawing, finishing, etc. was done

with hand tools. I spend the bulk

of my time working with hand

tools because I find them

peaceful and quiet, and for

relatively small jobs I believe

that I am faster and more

accurate working with them than

I would be with power tools.

This is the full size chest that I keep

most of my hand tools in. It's

constructed from cherry and black

walnut and has castors to move it from

place to place. It stays in my shop.

You can sign up for a 5 day class to

build a tool chest in western, MA in

Sept. 2012 at Heartwood School.

Project Blog

Spring 2012 Update

Jan 2012 Update

Autumn 2011 Update

July 2011 Summer Update

April 2011 Barn Update

February 2011 Barn Update

January 2011 Barn Update

Dec 2010 Update - Barn and Fireplace

Oct 2010 Update

Sept 2010 Update

Aug Update and Knee Braces

Scarf joint and barn update

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

Spring 2012 Update

Jan 2012 Update

Autumn 2011 Update

July 2011 Summer Update

April 2011 Barn Update

February 2011 Barn Update

January 2011 Barn Update

Dec 2010 Update - Barn and Fireplace

Oct 2010 Update

Sept 2010 Update

Aug Update and Knee Braces

Scarf joint and barn update

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

HOME -GALLERY - PROJECT BLOG - PHILOSOPHY - REVIEWS - TOOLCHEST - WINDSOR CHAIR - EMAIL