Summer 2012 Update - Entryway Design, Demo, and Rebuild.

With a little extra time between client projects this spring/summer, I've finally started to rebuild my own house. This house is a tricky project due to various factors: 1- The house was built in a decent fashion around 1900, but was very poorly renovated just prior to my wife and I buying it. 2- I'm a fairly finicky designer/builder and don't seem to have the ability to work below a certain level. 3- It's tempting to just leave it as is instead of facing the fact that renovating it means pretty much demolishing all of the work that has happened to the house since it was first built, and starting over.

Since we wanted to start with a project that would take less than a couple of months working alone, and stay under a few thousand dollars out of pocket, my wife and I agreed that the front entry way would come first. Even though this entry way will probably never be used more than occasionally, it seems energetically important to the house in general and serves as a template of what the rest of the house will look like.

With a little extra time between client projects this spring/summer, I've finally started to rebuild my own house. This house is a tricky project due to various factors: 1- The house was built in a decent fashion around 1900, but was very poorly renovated just prior to my wife and I buying it. 2- I'm a fairly finicky designer/builder and don't seem to have the ability to work below a certain level. 3- It's tempting to just leave it as is instead of facing the fact that renovating it means pretty much demolishing all of the work that has happened to the house since it was first built, and starting over.

Since we wanted to start with a project that would take less than a couple of months working alone, and stay under a few thousand dollars out of pocket, my wife and I agreed that the front entry way would come first. Even though this entry way will probably never be used more than occasionally, it seems energetically important to the house in general and serves as a template of what the rest of the house will look like.

As you can see, the house in general is pretty unappealling:

disproportionate trim detail, cheap anderson vinyl clad windows, a

nasty front door, strange sidelights, brown asphalt roof, strange

window and door casing on the inside....The shape of the copper roof

on the entry is slightly interesting, but so poorly trimmed and

finished that it doesn't really work. The upper windows are badly

proportioned, and there is no entablature, or decent cornerboards,

or water table ...

Step one for me was to generate a rough design drawing of what I thought that this house might look

like if it was built by a decent craftsman in around 1900.

This is what I came up with: 1- add

entabliture with windows contained

within it, 2- a nice level of trim with

columns on the front entry, 3- a very

simple porch to access entry, 4- nicely

sized windows with pediments, 5- a

water table board along the bottom, 6-

a nice simple front door with

sidelights, 7- a wooden roof, 8-

shutters to fill up some of the space

around the windows.

If this had been a client's project, I would have developed and refined the drawings further. Since I

was building it myself and in total control, I decided to start building and design on the fly. I enjoy

designing and building this way, as it feels more improvisational, like jazz, than completing a design

before building.

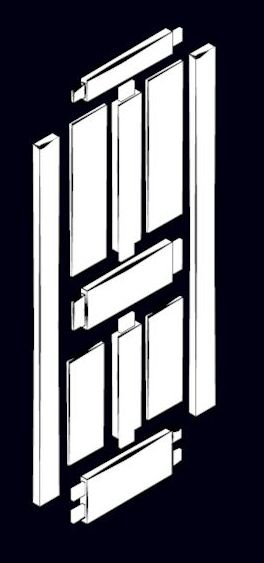

Since it was such an important part of this renovation, I decided to start on the door/sidelight unit. It

was an easy decision to build the door, sidelights, and lower panels from scratch. I'm not thrilled with

the quality of any of the commercially available units. I wanted: 1-simple design, 2- solid wood, 3-

weather resistant jambs, 4- high energy efficiency and durabilty, and have found that the the most

pleasant and economical way to get that is to build them. I also have a very nice shop that I delight in

using. I chose to build the door and sidelights out of cherry, with natural wood showing on the inside

and red paint on the outside. The inner panel would be cherry and the outer panel would be cedar for

weather resistance. The door and lower panels would be traditional mortise and tenon construction

with draw bored pegs, and I decided to use one panel of thermal glass on each sidelight with applied

grills instead of true divided lights. This was to allow a thinner look on the muntins. These pics should

show basically how the parts are cut and assembled into their finished components.

Exterior cedar flush panel with beads above, cherry

sidelights to the right, and interior cherry recessed panel

below. Lower right is the basic components to a door.

To the left are outside (beaded

flush panel) and inside (recessed

panel) of the dry assembled door.

The rails and styles are cherry

and the panels are pine.

As I built the components of the entry door unit, I also built the jamb that would hold it all together.

The jamb and threshold were built of white oak, which along with locust is probably the toughest and

most weather resistant wood that we have in our native new england.

I decided to paint the interior panels for

a bit of a modern feel. The panels and all

of the trim and jambs are linen white.

The exterior is painted with a solid stain

to avoid future peeling and the interior is

an acrylic paint. The natural wood is

finished with 3 coats of hand rubbed

tung oil. All parts of the door unit and

hardware get fit and installed while it's in

the shop, then taken apart and brought

to where it gets installed and

re-assembled. The sidelights are

thermo-paned glass and will ultimately

get an outside storm panel to triple

glaze. The door gets a mahogany storm

door and lower panels have 2" of high R

foam in between the panels. The doors

each have weather stripping on 4 sides,

so the entire unit is extremely tight.

Here my brother Eric is demolishing the old

entry. We stripped it down to framing, re-framed

window and door openings, and insulated the

walls with closed cell foam (approx. R38). The

simple porch is sitting on 4 -PT 6x6's set on

concrete pads below frost level. The porch

framing is PT 2x8, the risers will be azek, and the

deck and treads will be mahogany. We re-used the

existing foundation and rounded copper roof.

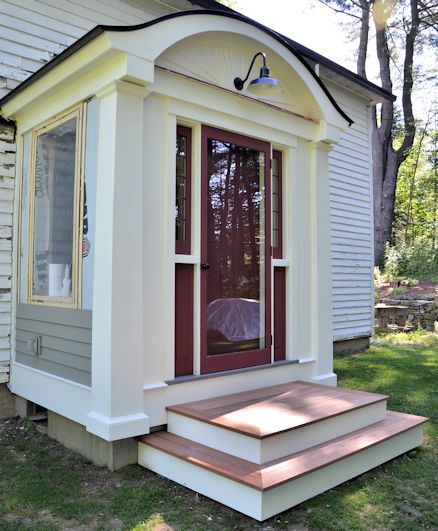

Right, we've installed the door unit and sealed it

with foam and rubber.

Left, the fr0nt of the entrance is trimmed in

semi-classical fashion. Columns and water

table are pretty typical Greek Doric

dimension, or as close as I could get with the

size of the existing house. Since I'm trying to

build in a way that will be relevant in the

50-100 years that I think is minimum

durability for a well built house, it makes

sense to stick with the Romans and Greeks in

styles that have lasted for thousands of years

to date. The simple mahogany storm door has

been added, built in simple mortise and tenon

style with tempered glass. I'm still waiting for

side windows to arrive, after which the siding

will be completed.

Right, a bit of a sunburst

pattern above the copper

drip detail and a barn

style light fixture.

Left, the cedar clapboard showing the circulating air space that

exists behind all of the woodwork. If you'd like for your siding,

trim, and roofing to have maximum life with minimum

maintanance, you'll always want to keep air circulating behind

the weather face of it. Above, the ultra simple front step with

mahogany decking which will ultimately get a coat of oil as it

dries out. Following are some details on the entry door.

Above and right, a spring loaded

weather-stripping which fits in a

dadoe in the bottom of door, and is

driven into the threshold when the

rod above is pushed into the jamb as

the door closes for an extremely tight

fit.

Below, the beaded, flush,

floating panel on the

outside of the entry door.

Left, I put extra slide bolts at the bottom and top of

both the main entry door and the storm door for

extra security and to be able to tighten door

against the weather-stripping for an absolutely

airtight fit. They will only be used when the door

won't be opened for a while, which will be often in

this case since doorway isn't in a heavy traffic

pattern. Below, different views of the entry from

outside and in. I especially like to design entryways

to be seen at night.

Below, finally the interior view showing the barrel vaulted ceiling and traditional trim

profile. Thank you for visiting, and if you enjoyed this blog, please forward it to anyone

that you think might enjoy it or find it useful. Any questions or comments, email right

here. Below the last picture you'll find a list of links to previous blogs. Enjoy your

summer!

Project Blog

Summer 2012 Entryway

Spring 2012 Update

Jan 2012 Update

Autumn 2011 Update

July 2011 Summer Update

April 2011 Barn Update

February 2011 Barn Update

January 2011 Barn Update

Dec 2010 Update - Barn and Fireplace

Oct 2010 Update

Sept 2010 Update

Aug Update and Knee Braces

Scarf joint and barn update

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

Summer 2012 Entryway

Spring 2012 Update

Jan 2012 Update

Autumn 2011 Update

July 2011 Summer Update

April 2011 Barn Update

February 2011 Barn Update

January 2011 Barn Update

Dec 2010 Update - Barn and Fireplace

Oct 2010 Update

Sept 2010 Update

Aug Update and Knee Braces

Scarf joint and barn update

Small Timber Framed Building

Fishing Cabin

Screen Porch

Stair Modelling

Container Based Structures

Off the Grid Timber Frame

How Green is Timber Framing?

Trim Detail, Geometric Proportion, and Realistic Modelling

Geometric Design Primer part 1

Geometric Design Part 2

Building Structures and Envelopes

Cabot Shores Cottage

April 2010 Update

May 2010 my own Barn

June 2010 Update

July 2010 Update

HOME -GALLERY - PROJECT BLOG - PHILOSOPHY - REVIEWS - TOOLCHEST - WINDSOR CHAIR - EMAIL